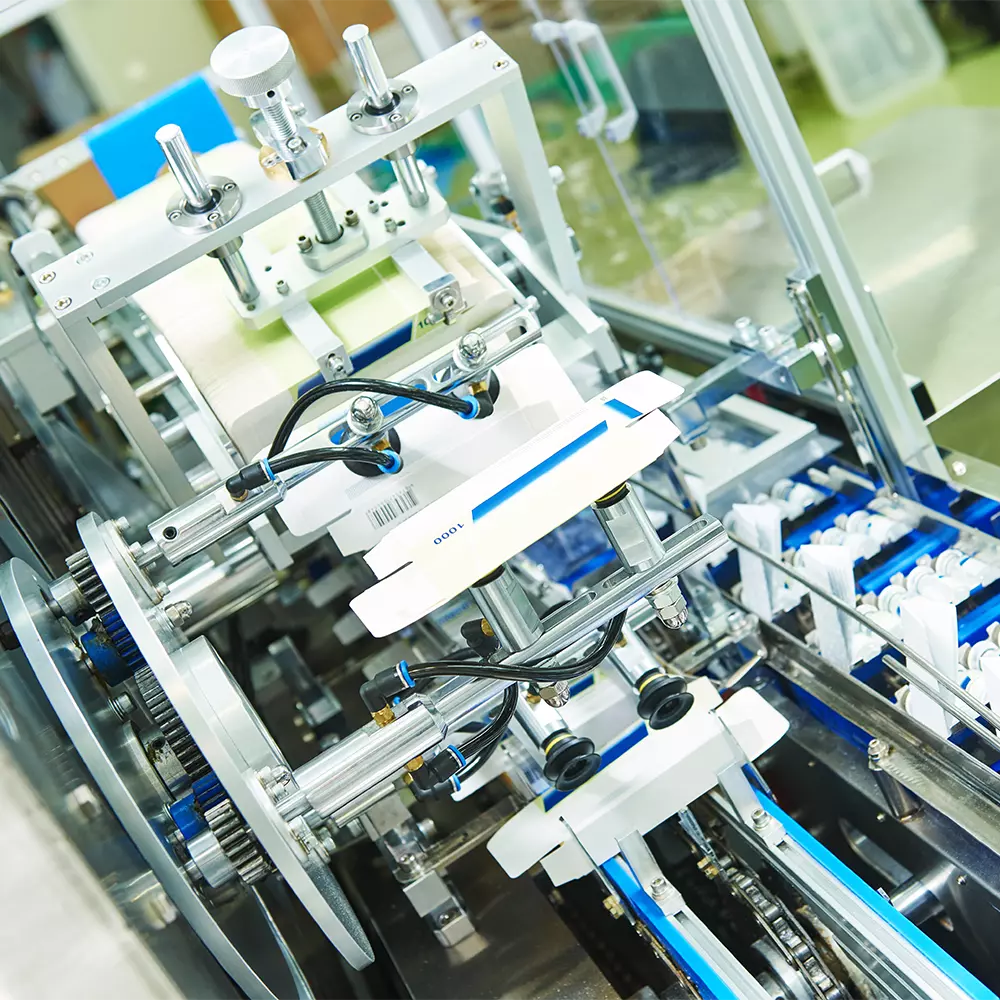

Working with ACA for more than 10 years has been a game-changer for our manufacturing process. The team’s expertise and commitment to excellence have helped us achieve significant improvements in efficiency and productivity. Their team is knowledgeable, responsive, full of innovative ideas (resulting in patents), and always willing to go the extra mile to ensure our satisfaction. ACAs attention to detail and commitment to understanding our specific needs has made them a valuable partner in our business growth. Their professionalism and dedication to customer success make them a trusted partner in the manufacturing industry.

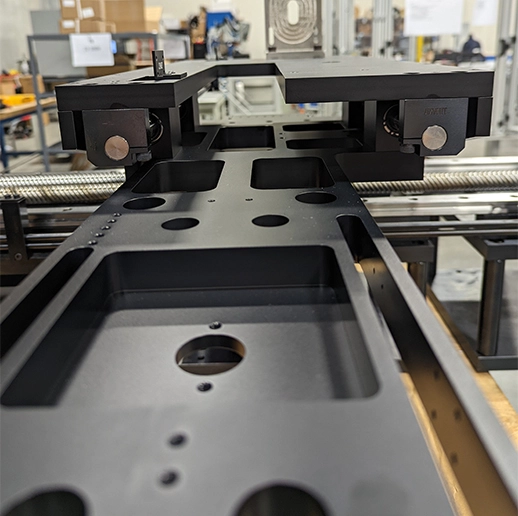

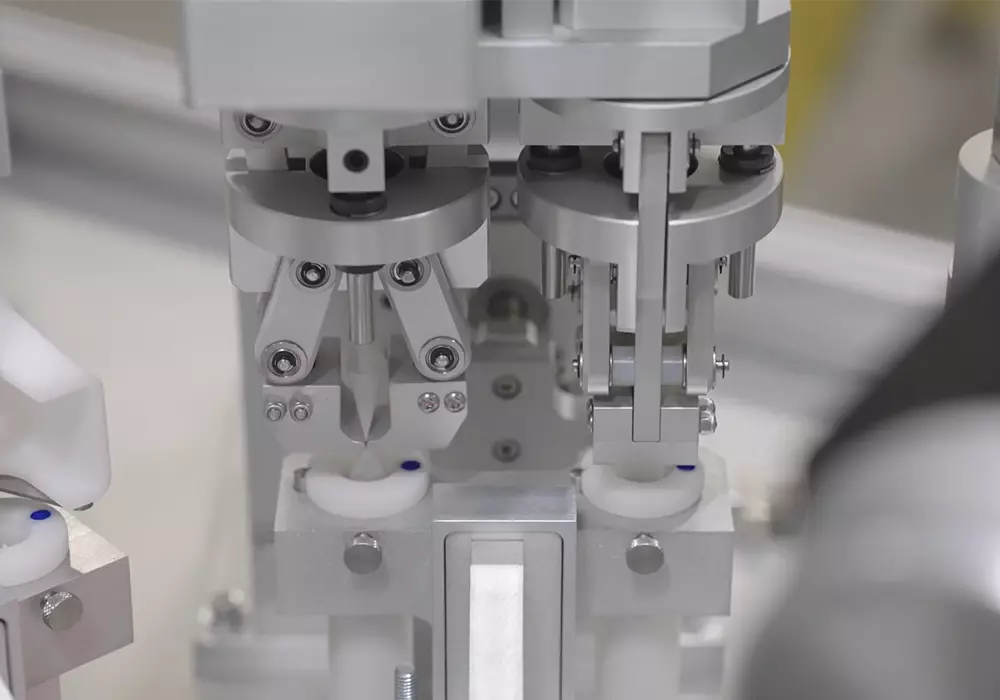

Capabilities

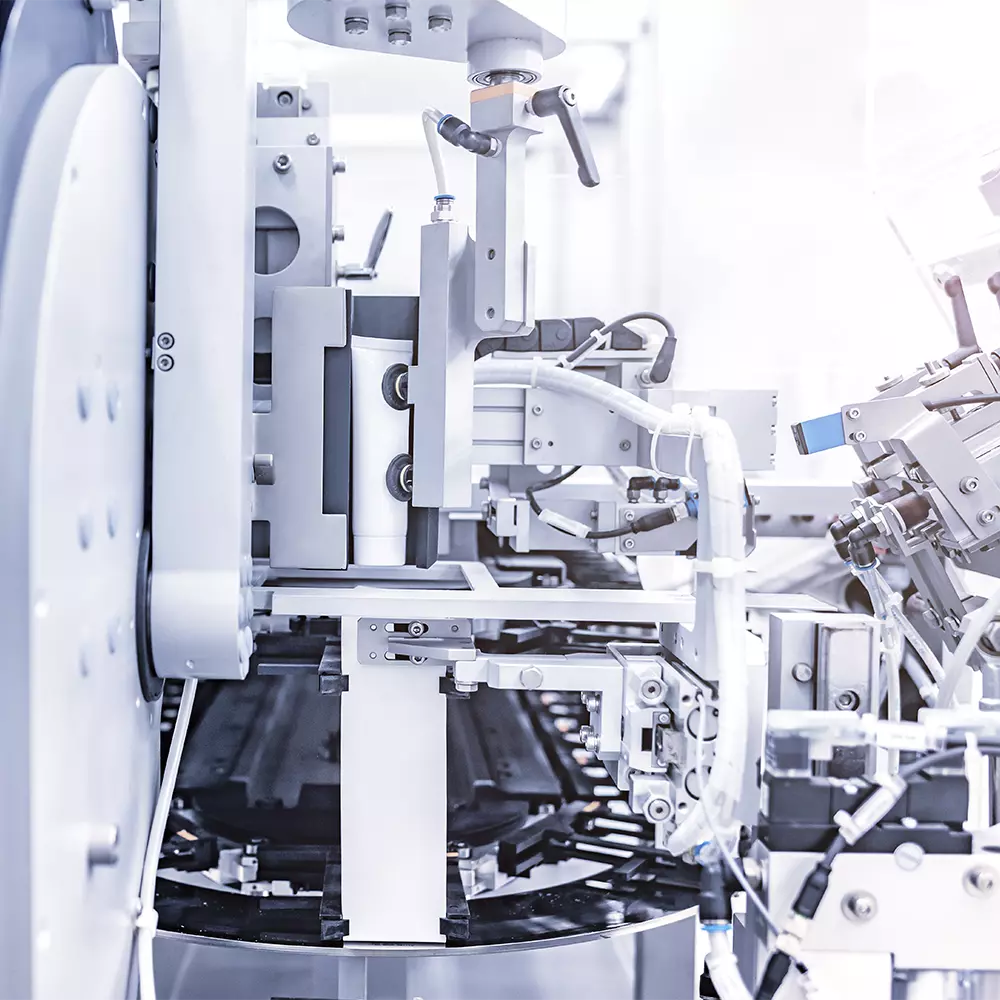

Industries We Serve

What Our Customers Are Saying

Some of Our Valued Clients

Our Mission

Revolutionizing the manufacturing industry through custom automation.

Our mission is to create machines and systems that address your operational challenges with transparent guidance every step of the way.

We pride ourselves on our adaptability, ensuring that our solutions are tailored to your specific needs regardless of your industry or environment. We invest in our associates, communities, and customers to deliver top-of-the-line systems to exceed your expectations.